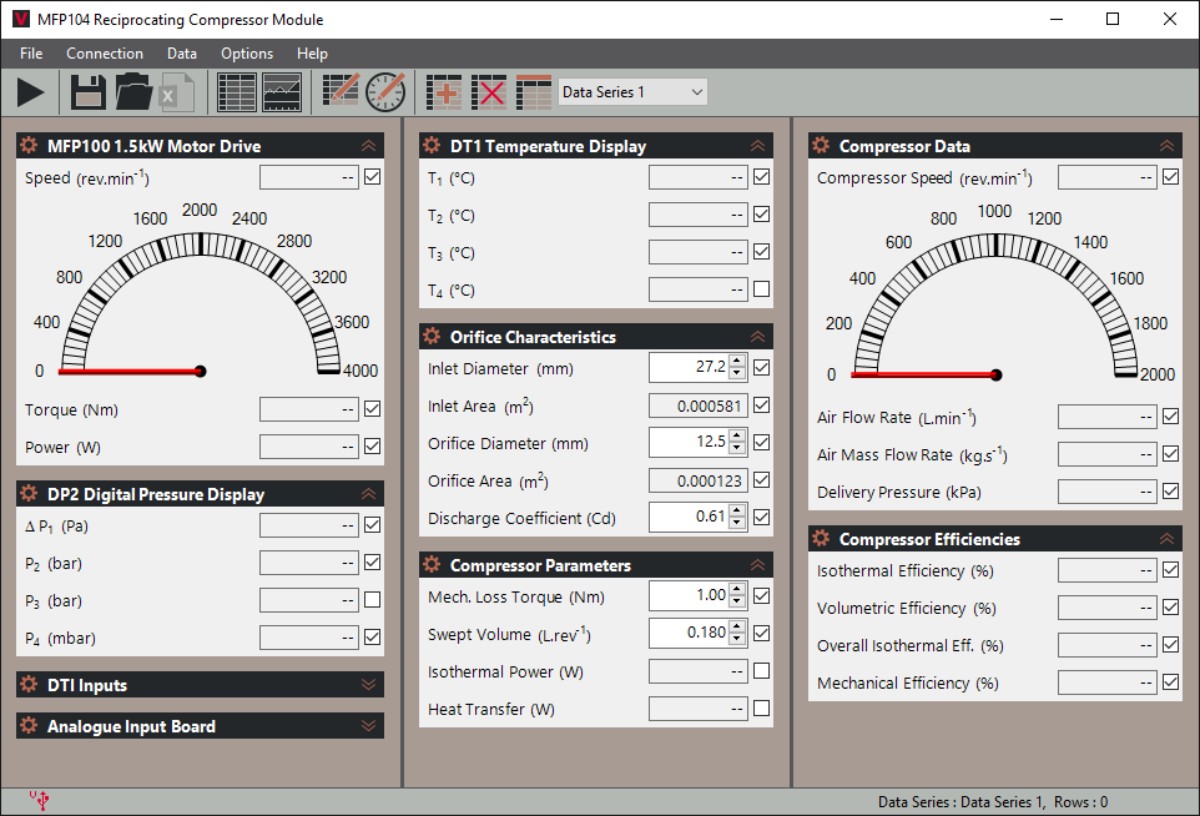

RECIPROCATING COMPRESSOR MODULE

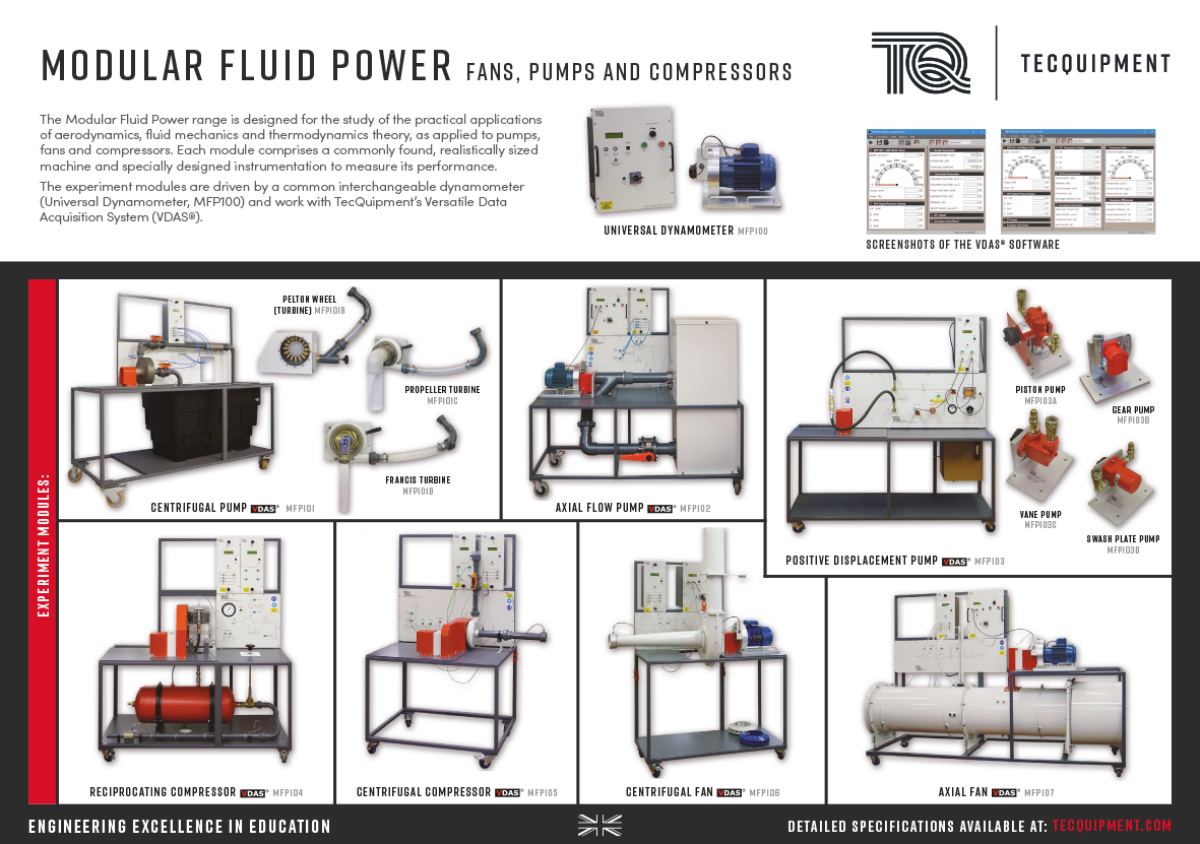

For use with and driven by the Universal Dynamometer (MFP100, available separately), the Reciprocating Compressor Module is part of TecQuipment’s Modular Fluid Power range. It is ideal for student experiments, demonstrations and projects.

Reciprocating compressors are common machines that provide compressed air for machines and tools. These can be air tools (saws, sanders and screwdrivers), paint spray equipment, pneumatic actuators and control systems. The module includes a small compressor with an air receiver and instrumentation, all mounted on a robust, mobile trolley for ease of use.

The separate Universal Dynamometer (MFP100) measures the speed, torque and power absorbed by the compressor. Speed is fully variable up to the maximum allowable for the compressor. Air enters the compressor, which then delivers it under pressure to the receiver. A valve releases pressure from the receiver to atmosphere through an orifice. The valve sets the pressure in the receiver and hence the flow rate; the orifice allows an accurate measurement of the mass flow rate of the outlet air. These values help students to discover how the compressor flow rate relates to the pressure delivered by the compressor.

Thermocouples measure temperatures at the inlet and delivery of the compressor, and upstream of the orifice. Electronic transducers measure the delivery pressure, nozzle differential pressure (flow rate) and the atmospheric (barometric) pressure. Also, for safety and good engineering standards, a Bourdon gauge shows the vessel pressure, even if the mains electricity fails. Digital displays show all the important pressures and temperatures.

For quick and reliable tests, TecQuipment can supply its optional Versatile Data Acquisition System (VDAS®). This gives accurate real-time data capture, monitoring and display, calculation and charting of all the important readings on a computer.

Learning outcomes

- Energy balance for a compressor

- Variation of compressor performance with pressure

- Variation of compressor performance with speed

- Mechanical, volumetric and isothermal efficiencies

- Thermodynamics of a compressor

MFP104 - Experiment

MFP104 - Experiment