Experiment

SM1011

THICK CYLINDER

A self-contained bench mounting experimental apparatus to enable students to investigate the distribution of radial and hoop stresses and strains throughout the wall of a thick cylinder and to compare the practical results with those predicted by theory.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611THICK CYLINDER

TecQuipment’s Thick Cylinder apparatus allows students to examine radial and hoop stresses and strains in the wall of a thick cylinder. They can then compare experiment results with the theoretical Lamé predictions. It clearly shows the principles, theories and analytical techniques, and provides effective, practical support to studies.

A sturdy base contains all parts of the Thick Cylinder apparatus. This forms a compact product, ideal for use on a workbench.

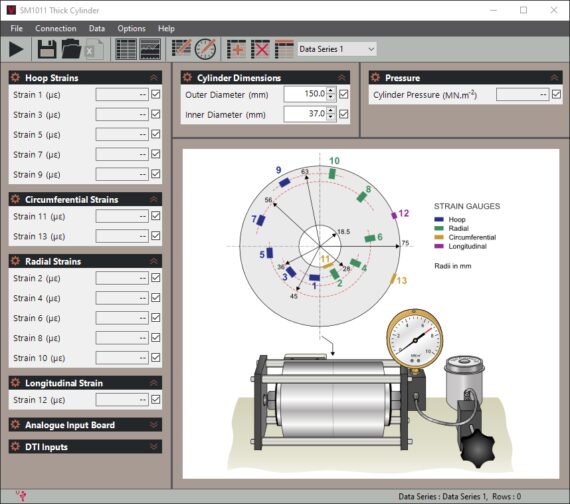

The apparatus consists of a thick-walled aluminium cylinder, held in a robust frame. The cylinder is in two halves, cemented together. One face of the joint has an eccentric shallow groove that contains ten strain gauges at precise radii and orientation. These gauges measure the radial and hoop strains. Jointing cement fills the groove. Strain gauges on the inner and outer walls of the cylinder measure longitudinal and circumferential strains. The cylinder contains oil. To stress the cylinder, students use a hydraulic hand-pump to pressurise the oil.

To perform experiments, students set the gauges to zero and use the pump to pressurise the cylinder. They take readings at several stages while increasing the pressure. The results can be taken by hand using the in-built display and pressure gauge and plotted by hand. Alternatively, they can use TecQuipment’s optional Versatile Data Acquisition System (VDAS®) to capture the data and plot the relevant graphs and export data. They then compare their results with calculations made using theory. A user guide is supplied with the Thick Cylinder apparatus. The guide includes full details of the equipment, detailed experiment procedures, theory and results.

For quick and reliable tests, TecQuipment’s optional VDAS® gives accurate real-time data capture, monitoring and display, calculation and charting of all important readings on a computer.

Learning outcomes

- Radial and hoop strains throughout the cylinder wall

- Radial and hoop stress distribution in the wall

- Longitudinal stress and strain at the outer surface

- Circumferential stress and strains at the inner and outer surfaces

- Comparison with Lamé predictions

- Principal stresses and maximum shear stress

- Appraisal of accuracy of location of strain gauges