Safety is paramount and needs to be viewed not just through a Covid lens. Remote control of equipment is a functionality that has sparked much discussion. The challenge for companies manufacturing equipment is compliance with Functional Safety requirements, which is distinctly non-trivial. In a previous role in an industrial lab, I vividly remember coming into work one day to find a materials lab completely flooded due to a leak in a piece of equipment that we had put together quickly to run unattended overnight. It did not have any provision for shutting off the water in case of a leak and we paid the price.

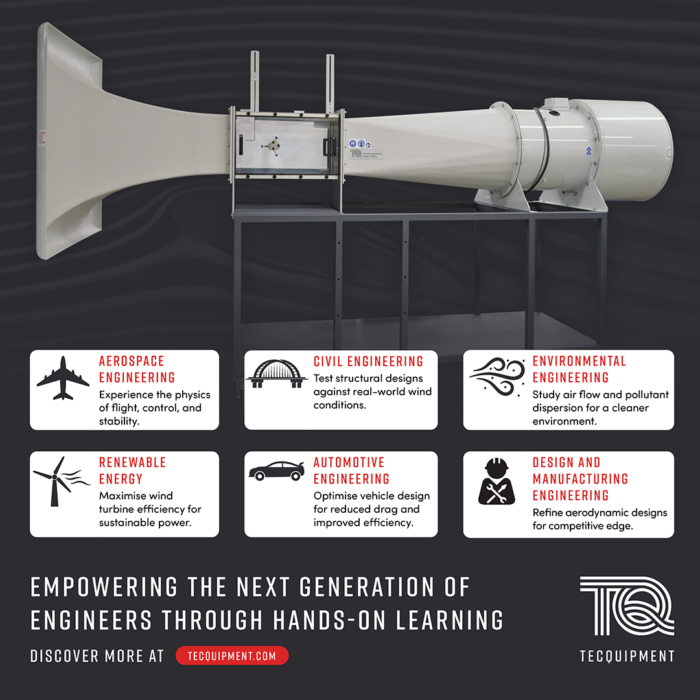

A massive part of helping form great engineers is enthusing students whilst embedding a real feel for engineering, so we need to look at how we integrate technologies to give the best possible learning outcomes that match the skills needed for employers and take into consideration different learning styles and constraints like space, funding and skills etc.

Industry 4.0 & IoT

Engineering education must keep up with technology used in the real world. Concepts such as IoT and Industry 4.0 (and Education 4.0) make it natural for us all to consider how such technology could be used to enhance engineering teaching equipment and enable students to gain the skillsets required for the current and future job market. Yet there are other factors at play to consider.

The Role of Engineering Empathy

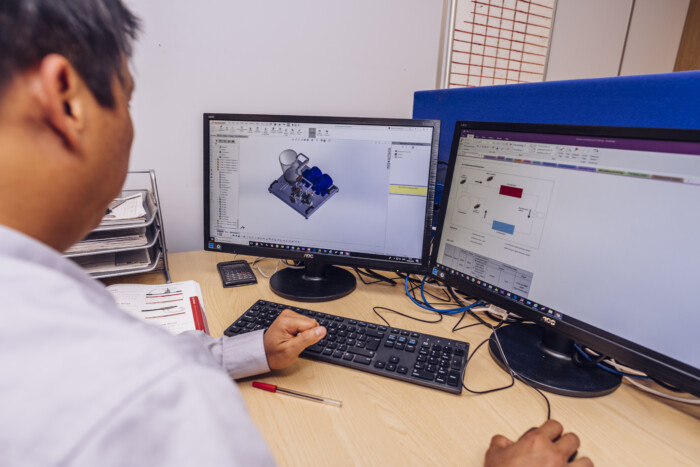

Time and time again we are told by our customers in Universities and Colleges around the globe that a critical part of preparing engineering students for the real world is giving them that “mechanical empathy” that only comes from practically experimenting in-person. I remember being told as a young engineer: “if it looks right it probably is right”. But that ability to judge whether something looks right is fundamentally associated with experience gained from hands-on activities, where you absorb a myriad of detail including sounds, smells, temperatures, forces, stiffnesses and proportions.

In many cases, manual control by way of a wheel, dial, pump etc. provide a physical interactivity that aids the learning and retention process. It’s the vibrations, resistance and general movement that students miss when this is taken out of the learning process, as is inevitable with fully remote learning.

Safety

Whilst remotely operated equipment offers the ultimate in Covid infection mitigation, there are significant issues around safety to be overcome as soon as equipment is configured to operate remotely.

- Integration of control mechanisms to provide ‘fail-safe’ in all situations

Manufacturers have to ensure any equipment put on the market is safe both in normal use and when exposed to any reasonably foreseeable abuse. This becomes much more difficult when equipment is configured for remote operation. Imagine, for example, the potential consequences of a lab technician being unaware a heat transfer experiment is being used remotely and trying to pick-up and move a piece of equipment that contains scalding hot water. That’s just one of the possible scenarios that need to be considered when designing for and assessing compliance with Functional Safety standards.

- Having a person present to override if something should go wrong

This could be seen as an option, but it is questionable whether equipment that can be operated remotely but needs someone to be present in case it goes wrong is compliant with global safety standards. And a competent person needs to be present to “machine watch”.

Of course, it’s perfectly feasible to design safe and effective equipment that can be operated remotely. However, it comes at a cost and the open question is whether the benefits outweigh those costs, especially when you factor in the learning outcomes that are lost when operating equipment remotely, compared to being hands-on.

Blended Learning

We firmly believe that hands-on practical learning is a fundamental part of the formation of high quality engineers. But that’s not to say things either will, or should, go back to the way they were done before Covid. As for what next, well let’s see. We brought you VDAS e-lab last year, allowing multiple students to remotely acquire experimental data in real-time, and are working with leading academics to bring exciting new technologies to market to enhance student experience and streamline the delivery of practical teaching . We continue to invest in new product development to provide tools that support and stimulate that process. There’s an exciting future ahead.