Experiment

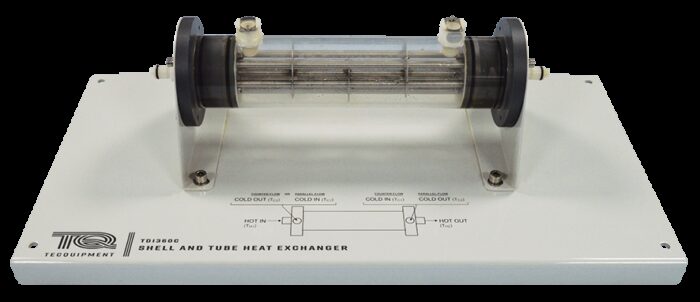

TD1360C

SHELL AND TUBE HEAT EXCHANGER

Small scale educational shell and tube heat exchanger.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611SHELL AND TUBE HEAT EXCHANGER

This heat exchanger is one of the most common type used in industry. This is because it is compact, but can work at higher pressures than other designs. It is a large tube (shell) which surrounds several smaller tubes (a bundle). One fluid passes through the shell, and the other fluid passes through the tube bundle, therefore transferring heat. Baffles around the bundle help to create a turbulent mixed flow.

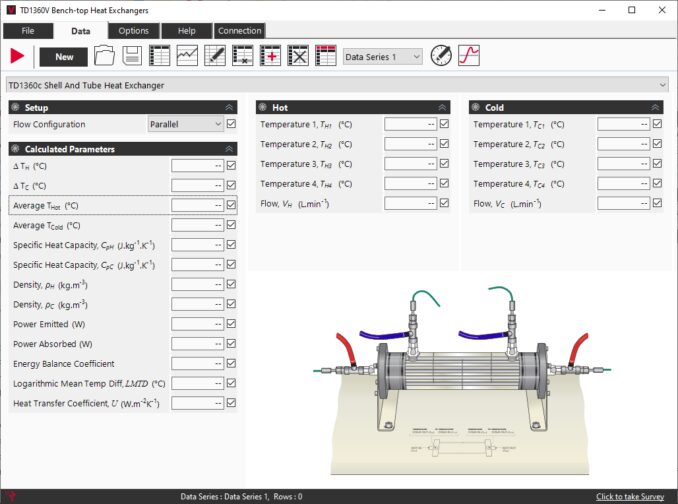

The Service Module (TD360) provides hot and cold water to the heat exchanger and all the instruments needed to measure its performance. All fluid connections to the heat exchanger are self-sealing quick connectors - for safety and simplicity. The hot and cold fluid streams have different connectors to reduce errors. Connecting the heat exchanger takes less than one minute.

The heat exchanger is on a bedplate that has a clear schematic diagram showing the connections. The bedplate fixes to the Service Module with thumbscrews.

Learning outcomes

- Demonstration of heat transfer from one fluid to another through a solid wall.

- Energy balance and efficiency calculations.

- Demonstration of parallel-flow and counter-flow operation of heat exchangers.

- Measurement of the heat transfer coefficient, and the effect of fluid flow rates and the driving force (temperature differential) upon it.

- Introduction to the logarithmic mean temperature difference in heat exchangers.

- Comparison of different types of heat exchanger in terms of performance, size and relative cost (only if you have two or more optional heat exchangers).