Experiment

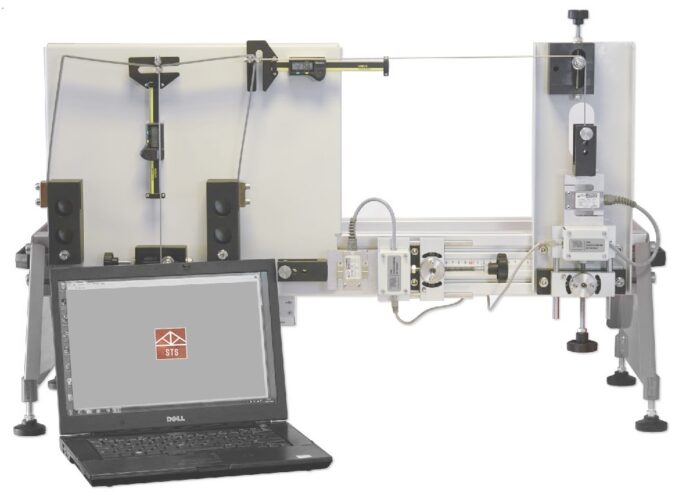

STS16

Plastic Bending of Portal Frames (Next Generation Structures)

Experiment for the study of plastic theory and limit state design in portal frames. Mounts on the Structures platform and connects to the Structures automatic data acquisition unit and software (VDAS® Onboard).

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611Plastic Bending of Portal Frames (Next Generation Structures)

One of a range of experiment modules that fit to the Structures platform (STS1, available separately), this product helps students to understand the nature of plastic deformation in hot-rolled mild steel portal frames that can undergo large plastic deformations. Similar frames at real-scale form parts of buildings with large internal spaces such as factories or warehouses.

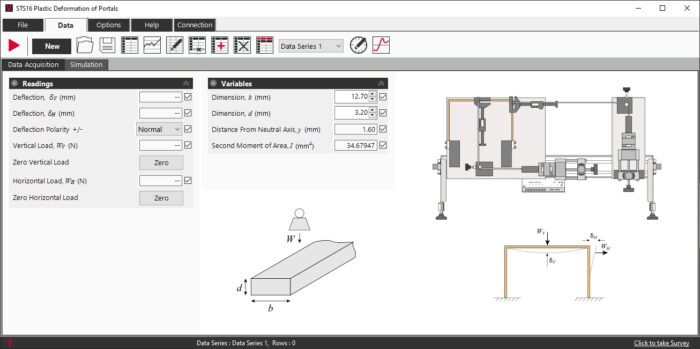

Students fit the specimen portal frame to fixing blocks that simulate fixed foundations, and apply loads. Load cells measure the applied forces and precision indicators measure the portal deformation. Each load cell applies and measures the load through cables at 90 degrees to the portal. This preserves the load direction as the portal deforms.

Students apply either vertical, horizontal or combined loads to the portal, forcing it to bend through the elastic region and into the plastic region where it deforms permanently, experiencing ‘plastic collapse’ and the formation of ‘plastic hinges’. This allows students to appreciate the ratio between yield moment and the fully plastic moment (shape or form factor), showing how this ratio provides an additional safety factor. It explains how a building may fail, but still withstand loads to allow people to safely leave before complete collapse. It also shows the interaction between the vertical and horizontal loads and the production of an interaction diagram to predict the failure mode. Students use textbook equations to predict the results, comparing them to measured results. This helps confirm the reliability of the textbook equations and the accuracy of the experiment results.

Note: The experiments are destructive tests, so you use each portal only once. This product includes a set of additional specimen portals (STS16A) to allow experiments ‘out of the box’, and a Vernier Caliper for accurate measurement of cross-section.

The deformation indicators have their own displays, but they can connect (with the load cells) to the USB interface hub of the Structures platform for computer display and data acquisition (VDAS® Onboard).

*There are 21 different experiments in the Next Generation Structures range. View them all in this easy to view flyer here.

Learning outcomes

- Elastic bending to plastic deformation of portal frames

- Collapse load and the formation of plastic ‘hinges’

- Yield stress

- Deformation due to single and combined loads on a portal frame

- Generating an interaction diagram

- Shape of a collapsed portal due to hinge formation

- Introduction to limit state design

- Shape or form factor and the additional factor of safety it provides