Understanding Continuous vs Intermittent Flow

The Continuous Supersonic Wind Tunnel (AF302) is one of two TecQuipment wind tunnels designed to explore supersonic flow. The first, the Intermittent Supersonic Wind Tunnel (AF300), provides a reduced runtime of around 5–6 seconds per test. In contrast, the Continuous Supersonic Wind Tunnel (AF302) offers a continuous airflow, allowing students and instructors to run extended experiments without time constraints for deeper analysis, repeatable measurements, and greater opportunities for collaborative discussions and observations in real time.

A Closer Look at the Design

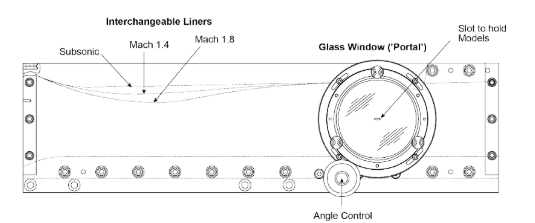

The Continuous Supersonic Wind Tunnel (AF302) is made up of several critical sections that together enable students to study airspeeds up to Mach 1.8.

Inlet Section: The specially shaped inlet ensures laminar, undisturbed airflow into the working section, creating ideal conditions for reliable experimentation.

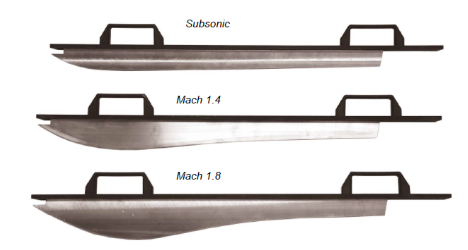

Working Section and Liners: This is where experiments take place. A set of interchangeable liners allows users to vary the maximum test speed. These include:

- Supersonic liner (for Mach 1.8)

- Mach 1.4 liner

- Subsonic liner

By fitting the appropriate liner, users directly control the speed of the flow through the working section. Each liner’s shape sets the approximate airspeed that passes through the nozzle, ultimately determining the test conditions for the experiment. By using different liners, educators can tailor the experiment to the learning objective.

Understanding Mach Number and the Laval Nozzle: The concept of Mach number is central to the experiments students perform using the Continuous Supersonic Wind Tunnel (AF302). It's a dimensionless value, calculated by dividing the velocity of an object (or airflow) by the speed of sound.

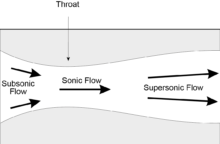

To achieve and sustain supersonic speeds, even with a powerful vacuum pump and motor, the system incorporates a Laval nozzle — a convergent-divergent shape (design featuring a rapid contraction followed by gradual expansion) that accelerates airflow beyond Mach 1. This nozzle accelerates the flow to the required supersonic velocities and is fundamental to understanding compressible flow and is a key feature of many real-world aerospace propulsion systems.

Vacuum System: The Continuous Supersonic Wind Tunnel (AF302) operates as a suction-type wind tunnel. Air is drawn through the tunnel by a large vacuum pump and motor, located in the enclosure. The suction design ensures steady, controllable flow.

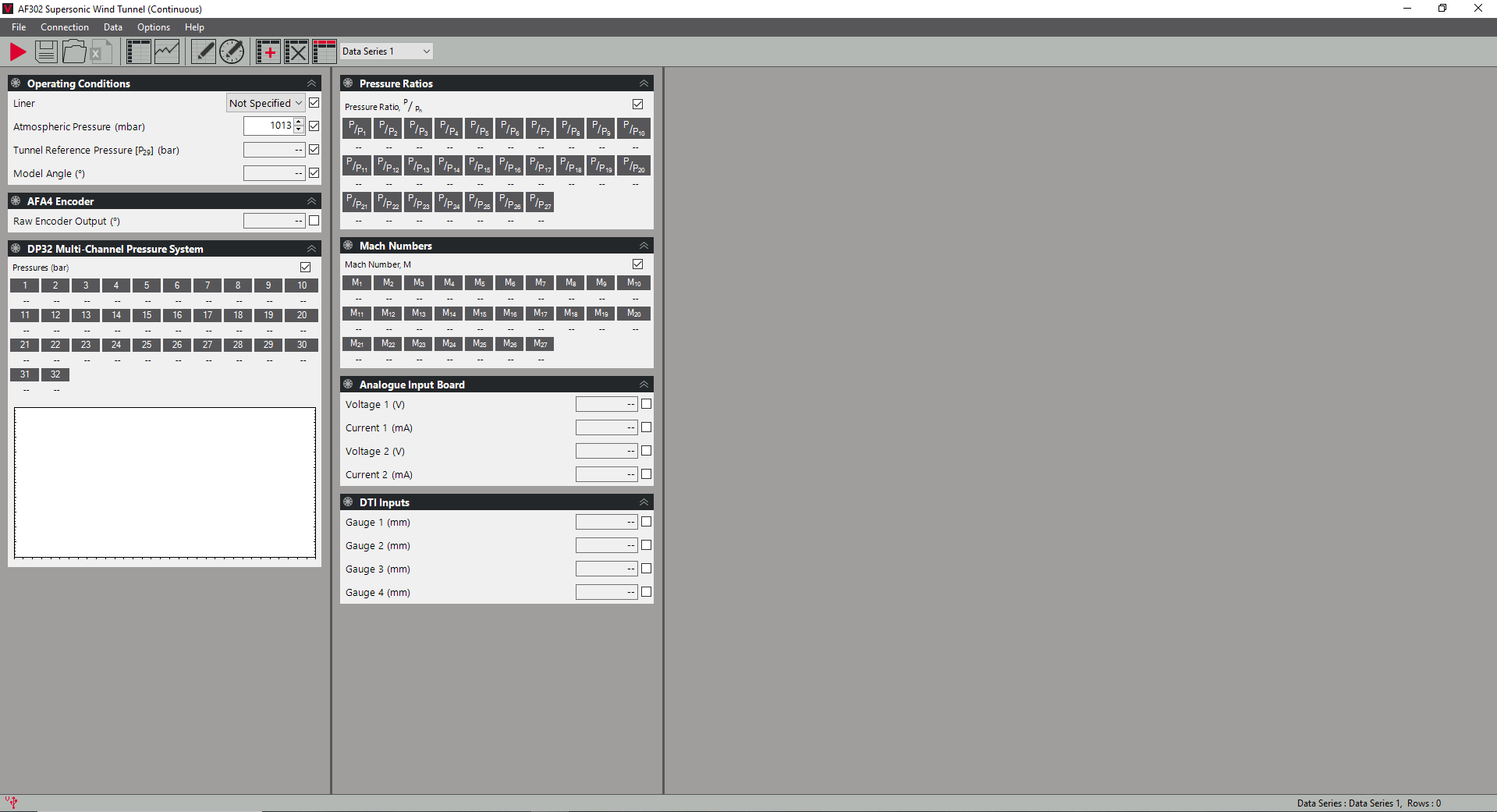

The Control Station and Data Capture: Lastly is the instrument frame, where users can control the wind tunnel and have access to the emergency stop, read pressures and observe a visual mimic of the nozzle showing where the tappings are located.

Using TecQuipment’s Versatile Data Acquisition System VDAS®, allows students to capture variables such as angle of attack, raw pressures, and Mach numbers in real time, and then visualise and export their data.

Continuous Supersonic Wind Tunnel (AF302) Experiments

Experiment 1: Measuring Pressure Distribution

The first core experiment involves measuring pressure distribution along the nozzle. Small pressure tappings located at intervals along the liner feed data to the pressure display on the instrument frame, where students observe the pressure values locally or on screen using VDAS®.

Using known dimensions of the test section (100 mm height and 25 mm width), students can calculate the area ratio and pressure ratio for each tapping point. This allows them to determine the Mach number at multiple points along the flow path. While these calculations can be done manually, TecQuipment’s VDAS® software interface displays key variables such as angle of attack, raw pressures, and calculated Mach numbers and simplifies the process, reduces error, and allows data export to Excel for further analysis.

These calculations help students relate physical pressure measurements to theoretical flow properties.

Experiment 2: Visualising Shock Waves

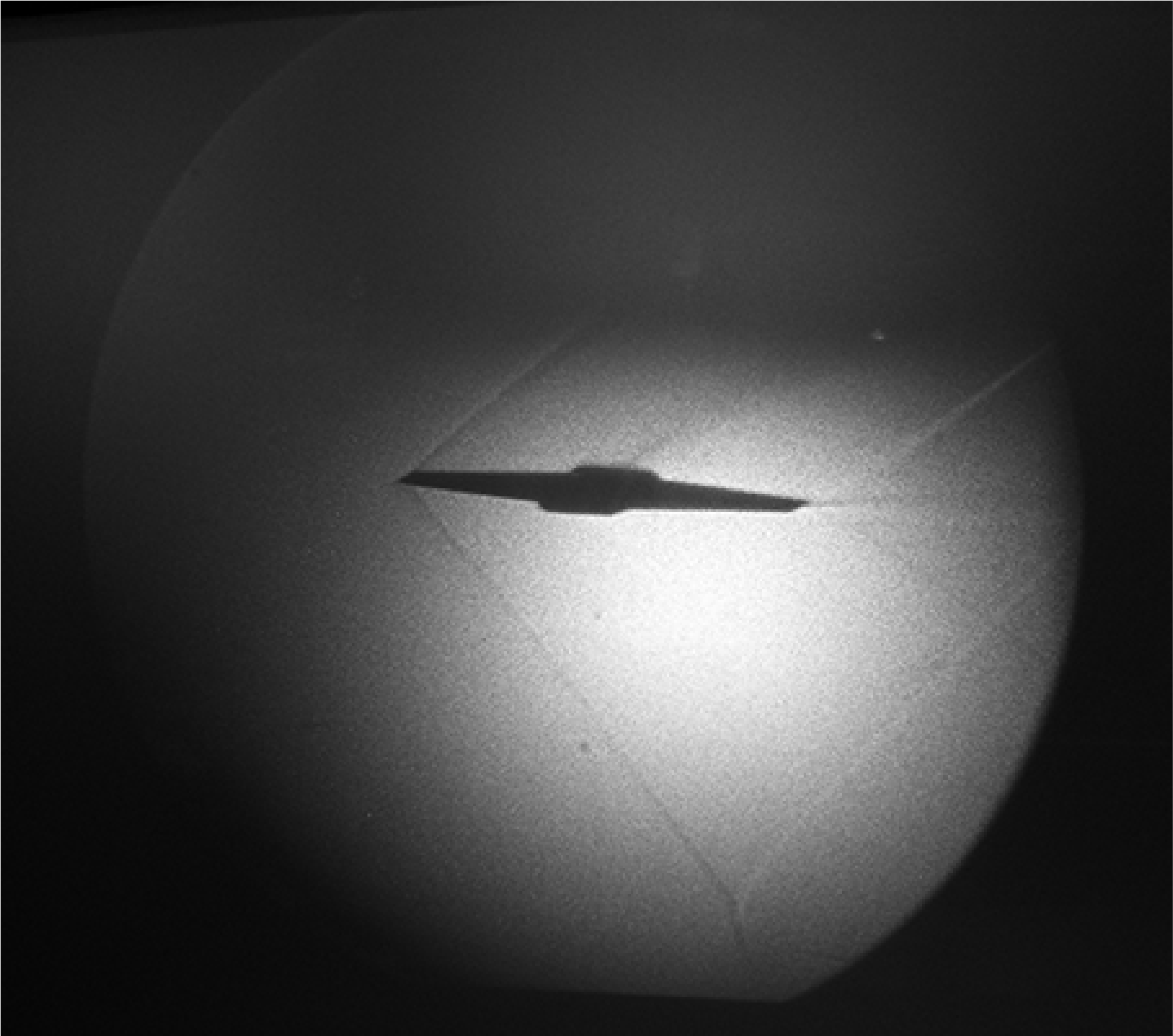

Equally, instructors can also use the Schlieren Apparatus (AF302A), an optional upgrade, to capture and analyse shock wave patterns in real time. These images can be used for further mathematical analysis, allowing students to apply principles of optical measurement, geometry, and wave behaviour in practical settings.

Bringing Supersonic Flow to Life

Students can also study shock and pressure waves around aerodynamic models mounted in the working section. The kit includes several model types, including, double-edge and single-edge (7° and 10°) configuration models and tapping model with pressure points. These models allow students to visualise how different geometries affect shockwave formation and flow separation.

Conclusion

The Continuous Supersonic Wind Tunnel (AF302) offers an exceptional platform for teaching supersonic aerodynamics in controlled educational lab settings. It combines accurate, real-time data with highly visual experiments that support both theoretical understanding and practical skills development.

For engineering educators, this equipment brings the theory of compressible flow to life — helping students understand the principles that underpin aerospace design, propulsion, and high-speed fluid dynamics.

Explore the product in more detail here: Supersonic Wind Tunnel – Continuous (AF302)