Experiment

AF302

SUPERSONIC WIND TUNNEL (CONTINUOUS)

A suction-type, continuous-operation supersonic (up to Mach 1.8) wind tunnel for investigations into subsonic and supersonic air flow around two-dimensional models. Also for analysis of the profile of the tunnel working section.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611SUPERSONIC WIND TUNNEL (CONTINUOUS)

A suction-type continuous-operation supersonic wind tunnel for investigations into subsonic and supersonic air flow. It also allows students to study air flow in two dimensions around aerodynamic models.

An instrument frame (supplied) holds a remote-control unit that controls a high-capacity vacuum pump (supplied). The pump creates low pressure downstream of the working section to draw air into the wind tunnel. A bypass duct, with a hand-operated valve, allows the operator to reduce the air flow through the working section, without disturbing the quality of the main air flow. This is useful for start-up and shutdown and for subsonic tests.

The working section of the wind tunnel is a convergent/divergent nozzle with a removable top part (‘liner’). The shape of the liner controls the maximum air velocity at the divergent part of the working section. Included are three different shaped liners.

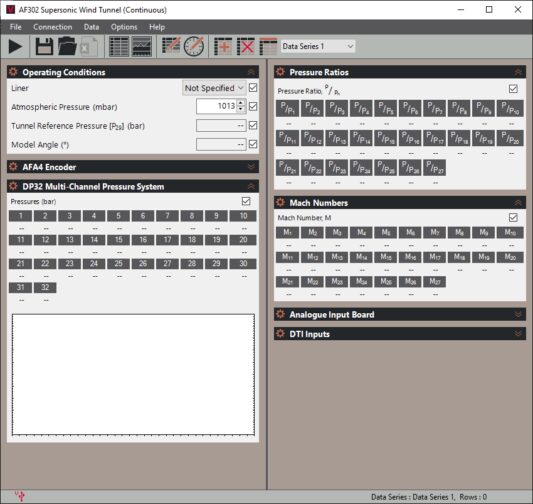

A selection of models are included with the equipment (one has pressure tappings) for experiments in two-dimensional flow. These fit in the ‘portal’ of the working section, flush to both windows. A geared mechanism allows students to adjust the incidence angle of the models. An encoder works with the optional VDAS® to measure the model angle.

Pressure tappings along the working section connect to a ‘mimic’ panel and multi-pressure display unit in the instrument frame. The display unit shows the pressures at the tappings. The display includes calibrated pressure sensors to measure pressures relative to atmosphere. It also shows the pressures on one of the models.

An analogue pressure gauge measures and displays the suction of the pump (tunnel reference pressure). This pressure line also connects to the multi-pressure display for data acquisition.

The equipment works with TecQuipment’s optional Versatile Data Acquisition System (VDAS®) and can quickly and conveniently connect to a frame-mounting interface unit (VDAS®-F, not included). Using VDAS® enables accurate real-time data capture, monitoring, display, calculation and charting of all relevant parameters on a suitable computer (computer not included).

The wind tunnel includes transparent windows in the working section. These are high-quality optical polycarbonate suitable for use with the optional Schlieren Apparatus (AF302a, available separately) enabling display and recording of images of high-speed flow.

Learning outcomes

- Pressure distribution along a convergent/divergent (Laval) nozzle with subsonic and supersonic air flow

- Comparison of theoretical and actual pressure distributions

- Comparison of actual and theoretical area ratios of a nozzle at supersonic air velocities (Mach numbers)

- Pressures around a two-dimensional model in subsonic and supersonic flow conditions, at different angles of incidence

- Lift coefficients for aerodynamic models in supersonic flow

- Shock waves and expansion patterns around a two-dimensional model in supersonic flow conditions (when used with the optional Schlieren apparatus).