Experiment

H6

DISCHARGE OVER A NOTCH

A tank and set of notch weirs for the study of flow regulation and measurement devices.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611DISCHARGE OVER A NOTCH

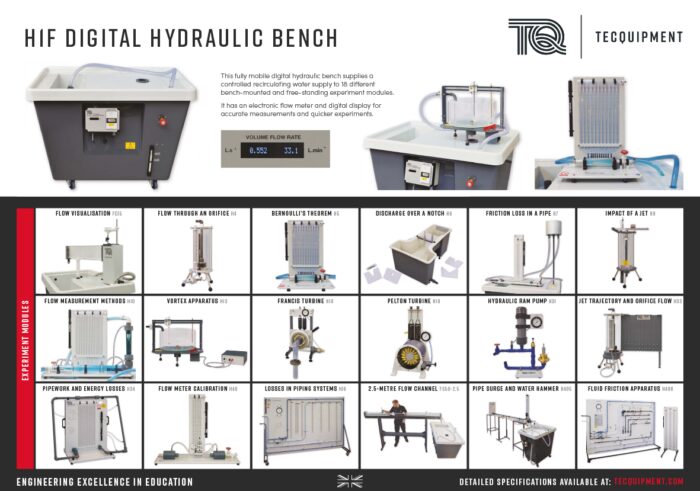

The Discharge over a Notch apparatus shows clearly the use of weirs as simple flow regulators. It works with and fits on the top of TecQuipment’s Digital Hydraulic Bench (H1F) (available separately). View the Digital Hydraulic Bench flyer here.

It allows students to do tests on relationships between upstream water level and weir discharge for various different shaped notches. They can then compare their results with theory.

The equipment is a moulded tank, the middle section of which forms a channel. One end of the tank is wide; the other end is deeper than the rest of the tank. Each weir fits in a sealed groove in the channel section. Plastic materials and corrosion-resistant finishes protect against corrosion. The hydraulic bench supplies water to the wide end of the tank. Water flows through the channel and over the weir, where the deep tank exit allows students to see the discharge. Students measure the free water surface using an adjustable depth gauge attached to a beam across the channel. The tank outlet fits on the hydraulic bench (available separately).

The equipment includes two different V-notch weirs and a rectangular notch weir. It also includes an advanced set of two weirs including a Cipoletti (trapezoidal) weir and a linear head/ flow weir. To do experiments, students regulate the flow using the hydraulic bench. They note the value of discharge and head, and reduce the flow. They repeat the readings for equal decrements in head, until the stream no longer springs clear of the notch. From their results they plot graphs of discharge rate against head, and also the logs of each.

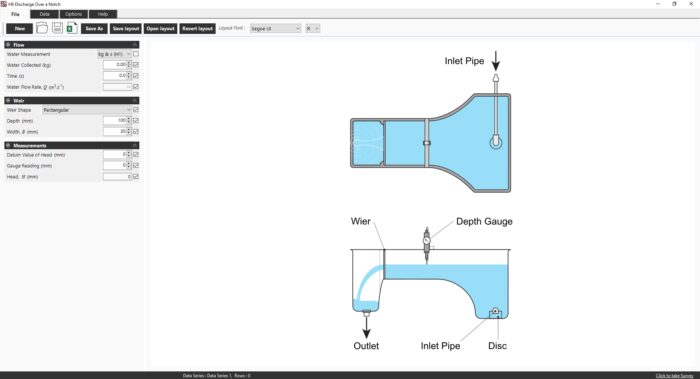

If required students can download TecQuipment’s Hydraulics Data Management System (HDMS) software onto a suitable computer (not supplied) to aid with entering, evaluating and presenting their data.

Hydraulics data management system (HDMS)

The HDMS is a complementary software tool designed to help students accurately record data from experiments associated with this apparatus. The software is intuitive and easy to use, with clear and convenient data display options, enabling students to run automatic calculations and export charts and results for further investigation.

Learning outcomes

Comprehensive study of flow over weirs, including:

- Investigation of head against discharge

- Coefficient of discharge for notches

- Rectangular and different angled V-notches