A

Ackermann Steering: A simple mechanism to approximate ideal steering where each wheel is given its own pivot. Ackermann steering solves most of the problems of turntable steering: the space required by each wheel is significantly reduced and the moment arm transmitting back imperfections in the road if reduced. Ackermann Steering refers to the geometric configuration that allows both race car front wheels to be steered at the appropriate angle to avoid tyre sliding.*

Adiabatic Humidification: is the process when finely atomized water is introduced into the air. Adiabatic humidification injects water (not steam) directly into the air using a spray mechanism or wetted medium, and the heat from the surrounding air causes the water to evaporate. Adiabatic Humidifiers are the ideal humidity solution when Steam or Gas are not available, they are also energy efficient and give precise Humidity Control.

Aerofoil: A curved surface structure designed to give the most reasonable amount of fluid to move through air, to create an aerodynamics force.

Afterburner (reheat): The component in jet engines to add additional fuel for an aeroplane to take off smoothly.

Air bearing: A bearing which separates moving surfaces apart by a layer of air.

Air flow:

- Around the Bend: The study of observing air flow around a bend to measure the pressure distribution.

- Visualisation: The study of observing air moment to reduce the risk of a product or process.

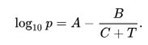

Antoine Equation: a simple equation created by French engineer Louis Charles Antoine to describe the correlation between the vapour pressure and temperature of components.

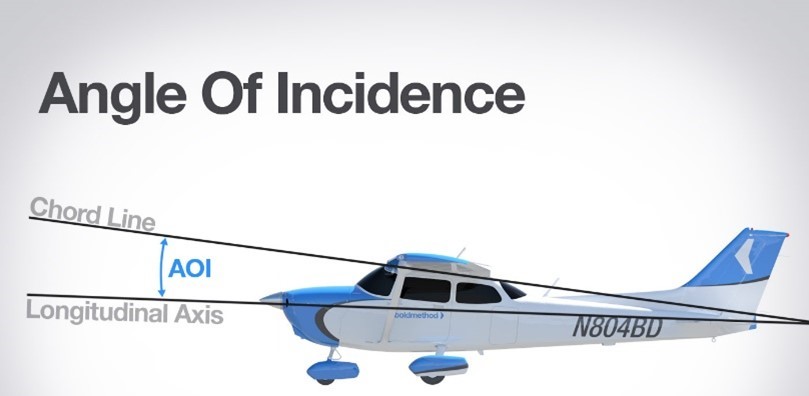

Angle of Incidence: in geometric optics, the angle of incidence is the angle between a ray incident on a surface and the line perpendicular to the surface at the point of incidence, called the normal. Aircraft angle of incidence: The angle of incidence is the angle between the aircraft longitudinal axis and the chord of the wing.*

Arch:

- Fixed: A statically structured arch designed to hang different masses on a weight hanger.

- Three-pinned: A three-pinned arch structure designed to hold various loads to show the relationship between the masses and horizontal thrust produced from the arch structure.

- Two-pinned: A two-pinned arch structure designed to hold various loads to show the relationship between the masses and horizontal thrust produced from the arch structure.

Archimedes Principle: A fluid mechanics law which states that a body is totally or partially immersed in a fluid is subject to the weight of the fluid in an upward direction.

Aspect Ratio: The ratio between the height and width of the aerofoil.

Automatic Data Acquisition: Cost-effective and user-friendly data acquisition software used on TecQuipment’s products.

B

Balance of Reciprocating Masses: Models that show how primary and secondary forces move in a back and forward motion and showing how to balance them.

Ball and Beam: A system in which a long beam can be titled by a servo or an electric motor with a ball rolling back and forth on top of a beam.

Ball and Hoop: A system that demonstrates the problems of speed and position control of a liquid in a container.

Bauschinger Effect: When different properties of materials become stressed/strained under a microscope and as a result changes the material’s properties.

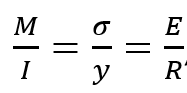

Bending Equation: the axial deformation of the beam due to external load that is applied perpendicularly to a longitudinal axis which finds application in applied mechanics. Where M= Bending moment, I= Moment of inertia of the area of cross-section, = bending stress, y= vertical distance from the neutral axis, E= Young’s modulus for the material of the beam, and. R= Radius of curvature.

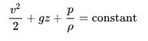

Bernoulli’s Equation: A simple equation created by Swiss physicist Daniel Bernoulli to describe the principle of conservation of energy and an increase in the speed of a fluid occurs, there will be a pressure decrease in the fluid energy.

Bevel Gear: are gears where the axes of the two shafts intersect and the tooth-bearing faces of the gears themselves are conically shaped.

Biaxial Stress Systems: A more general stress condition in which the stresses on an element acts in both x and y directions and all stress components in z-direction vanish. A two-dimensional state of stress in which two normal stresses are present.*

Boltzmann Law: A law defined by Stefan-Boltzmann to describe the power radiated from a body in terms of its temperature. The law states that the total energy radiated per unit surface area of a black body across all wavelengths per unit time is directly proportional to the fourth power of the black body’s temperature.

Boundary Layer: A layer of fluid (such as water or air) immediately surrounding an immersed moving object. A boundary layer is a thin layer of viscous fluid close to the solid surface of a wall in contact with a moving stream in which (within its thickness δ) the flow velocity varies from zero at the wall (where the flow “sticks” to the wall because of its viscosity) up to at the boundary.*

Bourdon Gauge: A pressure gauge with a coiled metallic tube which straightens out when pressure is exerted within it.

Bow’s Notation: A labelling method whereby the spaces in between any group of forces is labelled with a capital letter such that each force is then straddled by two letters.

Boyle’s Law: Boyle’s Law states that when the pressure of a given mass of an ideal gas is inversely proportional to its volume at a constant temperature.

Brinell Hardness Test: A method of measuring the hardness of a material by pressing a metal ball against the smooth material surface under standard test conditions.

C

Cantilever: A long beam with one end fixed and the other end free-standing, commonly used in bridge construction.

Cams: A wheel attached to a crankshaft that can be produced in any shape. A cam is a rotating or sliding piece in a mechanical linkage used especially in transforming rotary motion into linear motion

- Pear cams are called this as they have the shape of a pear. It remains stationary for half a turn then gently rises and falls. These are used to make carousel horses rise and fall.

- Heart-shaped or constant velocity cams have a shape similar to a heart. The follower rises and falls steadily with uniform velocity. There is no stationary period.

- Round or circular cams use an off-centre pivot to cause the follower to move up and down. The follower will rise and fall by a reasonably large amount. These can be seen in pistons, for example on steam engines.

- Snail or drop cams have the appearance of a snail shell. It causes the follower to remain stationary for half a turn before gently rising and suddenly falling. They can only work by rotating in one direction. Used on production lines to make regular holes or cuts in an item as it rotates and drops at regular intervals.

Cavitation: is a phenomenon in which the static pressure of a liquid reduces to below the liquid's vapour pressure, leading to the formation of small vapor-filled cavities in the liquid.

Centrifugal Force: This is the inertial force arising from the body’s inertia, which appears to act on a body moving in a circular motion and is directed away from the centre around when the body is moving.

Centripetal Force: A force that acts on a body in a circular motion and is then directed towards the centre whilst the body is moving.

Chezy Factor: A formula to describe the mean flow velocity of steady and turbulent open channel flow.

Chebyshev Linkage: created by Pafnuty Chebyshev, The Chebyshev linkage is a mechanical linkage that converts rotational motion to approximate straight-line motion.

Clement Desormes Experiment: This is a simple, quick, and effective experiment often seen in teaching laboratories for measuring the heat capacity ratio for air or any other gas.

Coandǎ Effect: The tendency of a jet of fluid emerging from an orifice to follow an adjacent flat or curved surface and to entrain fluid form the surroundings so that a region of lower pressure develops.

Composite Materials: is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Typical engineered composite materials include reinforced concrete and masonry composite wood such as plywood and reinforced plastics, such as fibre-reinforced polymer or fiberglass.

Compressor:

- Centrifugal: A compressor with rotating impeller blades to transfer energy to the gas.

- Reciprocating: A positive-displacement compressor that uses pistons by a crankshaft to deliver gases at high pressure.

Control:

- Cascade: A control algorithm in which the output of one loop provides the target for another loop.

- Distributed: A computerised control system for a process with a large number of control loops, in which autonomous controllers are distributed throughout the system.

- Multivariable: A system that interacts strongly when there are more than one input and more than one output. A disturbance to any input will cause a change of response from at least one output.

- Split range control: When the output of the controller is split and sent to two or more control valves.

Confined Aquifer: is an aquifer below the land surface that is saturated with water. Layers of impermeable material are both above and below the aquifer, causing it to be under pressure so that when the aquifer is penetrated by a well, the water will rise above the top of the aquifer.

Coplanar Forces: Coplanar force systems have all the forces acting in in one plane. They may be concurrent, parallel, non-concurrent or non-parallel.

Coriolis Force: An apparent force that results of the earth’s rotation deflecting moving objects, (such as projectiles or air currents) to the right in the northern hemisphere and to the left of the southern hemisphere.

Crank Motion: A crank is an arm attached at a right angle to a rotating shaft by which circular motion is imparted to or received from the shaft. When combined with a connecting rod, it can be used to convert circular motion into reciprocating motion, or vice versa.

Creep: Creep refers to a material science concept that describes the likelihood of a material to deform under an applied force of mechanical stress. Creep may also be known as material creep or cold flow. Creep occurs due to prolonged exposure to applicable forces below the yield strength of the receiving metal. It can be observed to have greater impact when a metal is exposed to increased levels of heat. Creep is a type of deformation that is important and experienced in a wide range of industries ranging from nuclear power plants, jet engines and even heat exchangers.

There are three main stages of creep:

- Primary creep: Starts at an increased rate and slows with time due to material hardening.

- Secondary creep: Has a relatively steady rate.

- Tertiary creep: Has an accelerated rate and ends when the material breaks.

Creep Recovery: In a creep recovery experiment, a sample is subjected to an instantaneous load for a certain time, and the dimensional changes as a function of time are recorded after removal of the load.

Critical hydraulic gradient: is defined by the hydraulic gradient where particles start to outflow from soil samples.

D

Darcy’s Law: Darcy’s Law states that the velocity of flow of a liquid through a medium due to differences in pressure is proportional to the pressure gradient in the direction of flow.

Discharge of Coefficient: The ratio of the actual discharge to the theoretical discharge.

Drag Coefficient: The measure of the effectiveness of a streamline aerodynamic body shape in reducing the air resistance to the forward motion of an aeroplane.

Dropwise Condensation: The condensate liquid which is collected in the form of countless droplets of varying diameters on a condensing surface, instead of forming a continuous film and does not wet the solid cooling surface.

Dunkerley’s Method: is used in mechanical engineering to determine the critical speed of a shaft-rotor system.

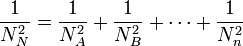

Dunkerley’s Formula (approximation): The whirling frequency of a symmetric cross section of a given length between two points is given by: RPM where E = young's modulus I = Second moment of area, m = mass of the shaft, L= length of the shaft between points. A shaft with weights added will have an angular velocity of N (rpm) equivalent as follows:

Dynamic Balancing: is a way of balancing machines by rotating parts quickly and measuring the imbalance using electronic equipment. The imbalance measured can then be corrected by adding or subtracting weight from the rotating parts until the vibration is reduced.

Dynamometer: An instrument which measures the power output of an engine.

E

Eccentric Loading: Eccentric load is defined as the load whose line of action does not pass through the axis of the column, but also line of action of load passes through a point away from the axis of the column.

Emissivity: The ratio of the energy radiated from a material surface compared to the energy radiated from a perfect emitter at the same temperature and wavelength under the same condition.

Euler Buckling Load: In civil engineering, the structural member is exposed to compression stress at particular level, it buckles outwards which is known as buckling. The load at which the compression-member deflects is called the Buckling load or critical load.

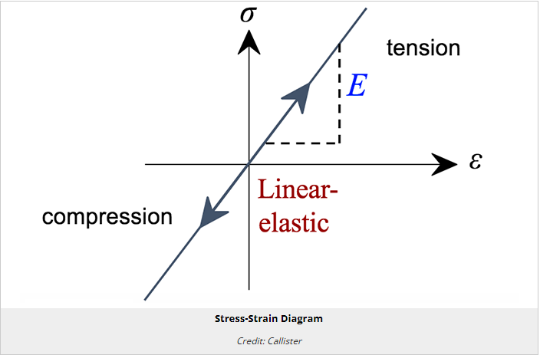

Elastic Region: It is the region where the material can be deformed and when released will return back to its original configuration. Many metals in the elastic region have a resulting strain that is proportional to the tensile load when the applied tensile load is small. Mathematically, this can be written as σ=Eε , and more generally is known as a form of Hooke's law.

Ericksen Number: Gives a measure of the ductility of the sheet in the plane of drawing under biaxial stress conditions.

Extensometer: A device that is used to measure changes in the length of an object. It is a useful device for any stress-strain measurement and tensile tests.

F

Fan:

- Axial: A fan that causes gas to flow through in an axial direction, parallel to the blade’s rotation. It is designed to produce a pressure difference and force to flow through the fan.

- Centrifugal: A mechanical device for moving air or other gases in a direction at an angle to the incoming fluid. They are typically used for transporting gases or materials in ventilation systems for buildings.

Fixed end moment beam: The fixed end moments are reaction moments developed in a beam member under certain load conditions with both ends fixed.

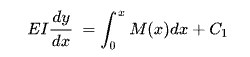

Flexural Rigidity: Flexural rigidity is defined as the force couple required to bend a fixed non-rigid structure by one unit of curvature, or as the resistance offered by a structure while undergoing bending. In a beam or rod, flexural rigidity (defined as EI) varies along the length as a function of x shown in the following equation:

Flow:

- Laminar: Also known as streamline flow occurs when fluid flow is in parallel layers, with no disruption between the layers.

- Turbulent: A fluid motion which has a chaotic change in pressure and flow velocity. This is normally observed on surfs and fast-flowing rivers.

- Visualisation: A visible flow pattern in air or water, making the flow pattern visible to the naked eye.

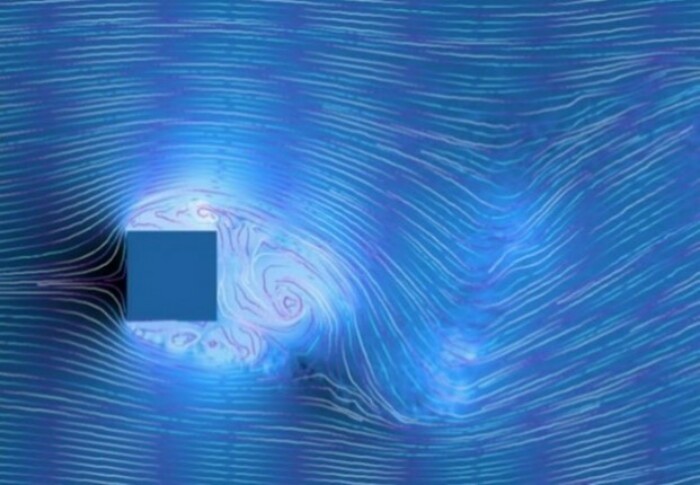

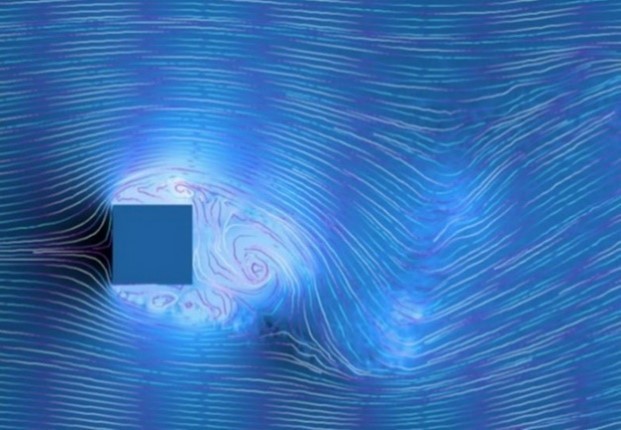

Flow Past Bluff: The major characteristic of flow over the bluff body is the development of a turbulent wake with a recirculation, which has a principal effect on the drag acting on the bluff-body. This type of flow structure is characterized by a flow separation zone, followed by turbulent eddies in the wake flow zone A bluff body is an object that, due to its shape, causes separated flow over most of its surface. This contrasts with a streamlined body, like an aerofoil, which is aligned in the stream and causes less flow separation.

Flow Visualisation: in fluid dynamics is used to make the flow patterns visible, to get qualitative or quantitative information on them.

Fluidics: the study and technique of using small interacting flows and fluid jets for functions usually performed by electronic devices.

Flywheel: A mechanical device specifically designed to efficiently store rotational energy. They also resist changes in rotational speed by their moment of inertia.

Forces:

- Concurrent: When all the forces pass through a common point within a parallel force system.

- Coplanar: When all the forces are acting on the same plane, it is known as the coplanar force system.

Fracture Energy: A material property which requires energy to an open unit area of a crack surface.

Free Vortex (irrotational vortex): one in which the fluid mass rotates without any external impressed contact force. The whole fluid mass rotates either due to fluid pressure itself or the gravity or due to rotation previously imparted.

Froude Number: A dimensionless number used in hydrodynamics to indicate how well a particular model works in relation to a real system.

––––––––––––––––––––––––––––––––––––––––––––

We hope you found this glossary of terms helpful in aiding your learning, to move onto the next section of our Mechanical and Civil engineering principles glossary G-L follow the link here!