Experiment

H19

PELTON TURBINE

A compact experiment for use with the Hydraulic Bench to demonstrate how a Pelton turbine works and to test its performance.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611PELTON TURBINE

Shows students how an impulse (Pelton) turbine works and tests its performance. The Pelton wheel is an important and efficient fluid power machine, used in many applications.

The unit consists of a Pelton wheel mounted in a corrosion-resistant enclosure. A transparent front panel allows students to see the turbine working. An optional Stroboscope (ST1, available separately) can ‘freeze’ the image of the turbine to help students better understand how it works.

An adjustable spear valve directs a jet of water through a nozzle to the buckets of the Pelton wheel to make it turn. Manual adjustment of the spear valve controls the water jet from the nozzle.

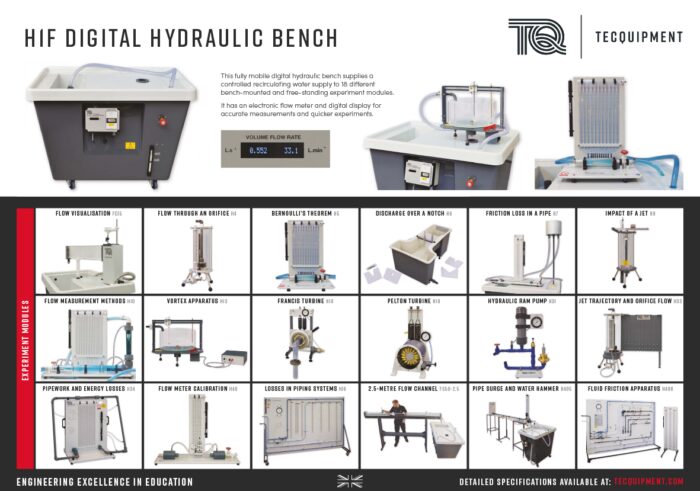

The turbine includes all pipes and fittings to connect it to TecQuipment’s Digital Hydraulic Bench (H1F, available separately). The hydraulic bench also measures flow rate. The Optical Tachometer (OT1, available separately) can measure the speed of rotation of the turbine.

A simple mechanical brake and spring balance assembly attached to the shaft of the Pelton wheel applies a variable mechanical load (torque). Students use this with the speed (from the optional tachometer) to find power absorbed by the turbine. A gauge measures inlet pressure.

Students adjust the spear valve and measure inlet pressure, flow rate and torque (and speed with the optional tachometer). They plot these values to find the turbine performance.

View the Digital Hydraulic Bench flyer here.

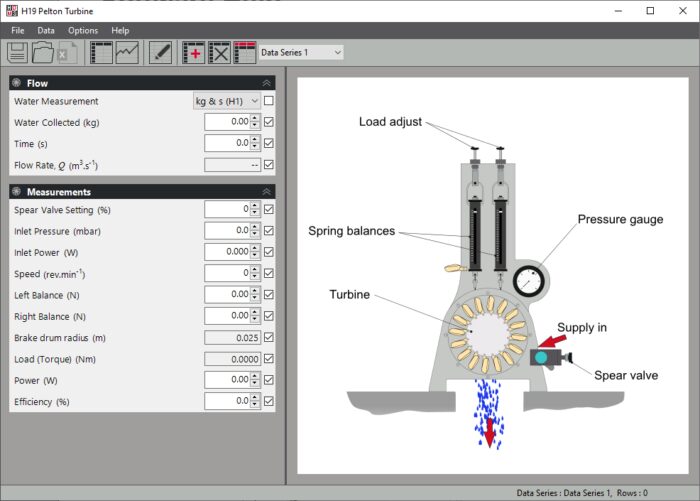

Hydraulics data management system (HDMS)

The HDMS is a complementary software tool designed to help students accurately record data from experiments associated with this apparatus. The software is intuitive and easy to use, with clear and convenient data display options, enabling students to run automatic calculations and export charts and results for further investigation.

Learning outcomes

- Performance charts of power, speed, torque and efficiency

- The effect of spear valve position