We spoke with the dedicated technical team to understand how TecQuipment’s solutions are being used to enhance student learning across civil, mechanical, automotive, and aerospace engineering courses.

Watch our full case study video delving into the teaching curriculum and the products shaping the engineering students of Hertfordshire here, and continue reading about five key TecQuipment products the academics at Hertfordshire enjoy working with.

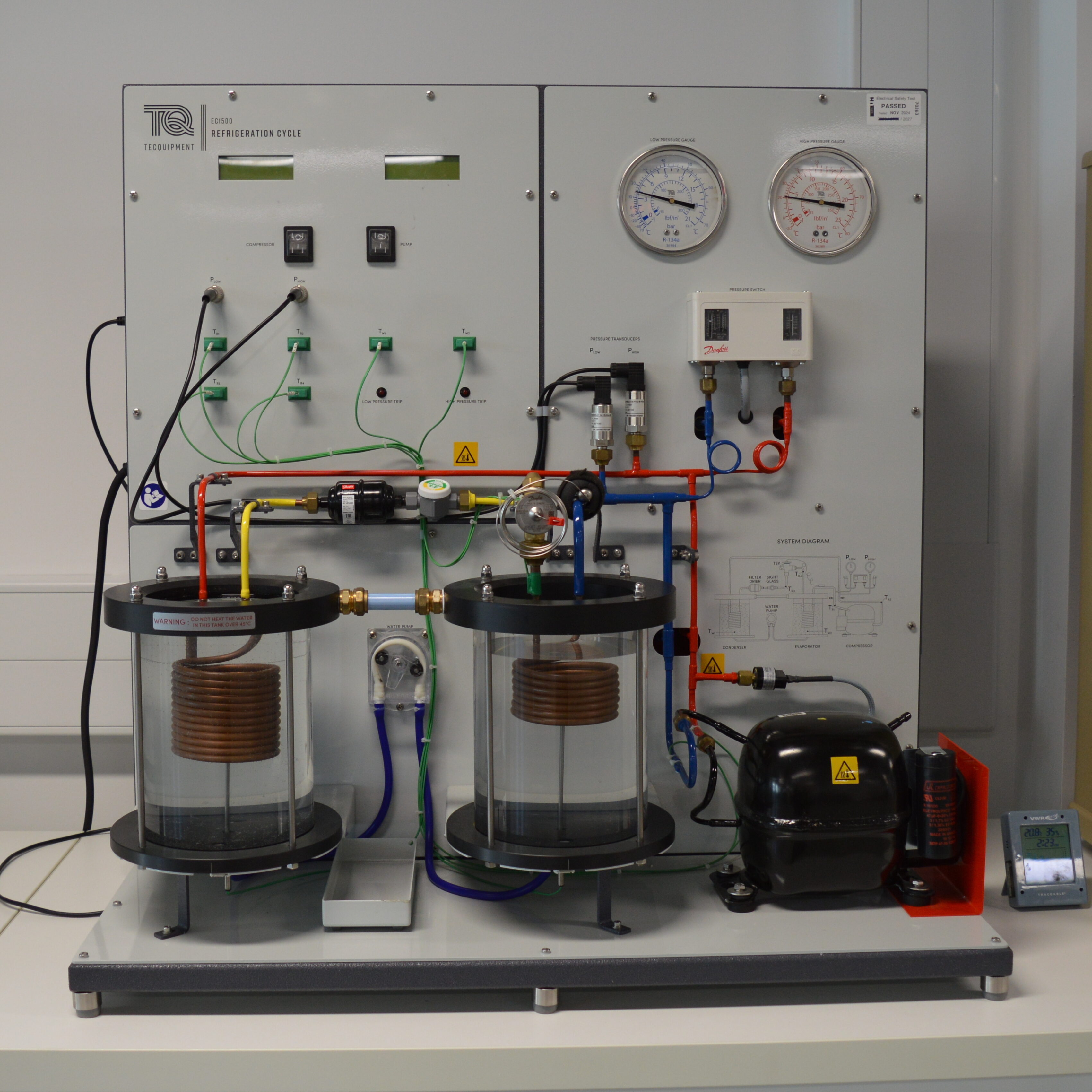

A Seamless Blend of Physical and Digital Learning: Teaching the Refrigeration Cycle

The Refrigeration Cycle Apparatus (EC1500V) plays a vital role in helping the mechanical, automotive, and thermodynamics engineering students understand key thermodynamics processes like vapour compression, refrigeration or heat pump cycle through visual and measurable results.

Students begin by switching on the system and collecting real-time data using TecQuipment’s Versatile Data Acquisition System (VDAS®). This digital interface allows them to track parameters such as pressure and temperature throughout the cycle, alongside traditional analogue gauges that provide a visual representation of system behaviour.

The blend of physical instrumentation and digital data makes it possible to teach the refrigeration cycle from both a theoretical and practical perspective—reinforcing how components like compressors and thermostatic expansion valves contribute to the overall energy balance of the system.

Alex Kingstrom, Technician Commitment Lead and Technical Manager in the School of Physics, Engineering, Computer Science (SPECS), shared his enthusiasm for the Refrigeration Cycle experiment (EC1500V).

“This unit allows our students to grasp thermodynamic principles visually and interactively,” he said. “The VDAS® software is a real game changer—it provides accurate digital readouts of experimental data, while the physical gauges reinforce a tangible understanding of system behaviour. Students get the best of both worlds.”

Investigating Open Channel Flow and Sediment Transport

Hydraulics students studying open channel flow, sediment transport, and wave dynamics use the 5 Metre Flume (FC50), and 5 Metre Flow and Sediment Transport Channel (FC80.5) as a central part of their curriculum. The 5 Metre Flow and Sediment Transport Channel (FC80.5) includes features such as a sluice gate to control flow, a wave generator to replicate real-world coastal conditions, and a dye injector to visualise turbulence and flow patterns.

Over time, students can observe the formation of sediment features such as dunes, tracking how flow conditions influence the shape, size, and movement of material across the flume bed. By measuring the crest and trough of these features, learners explore sediment transport mechanics and develop a deeper understanding of wave-fluid interactions—critical knowledge for applications in coastal and civil engineering.

Senior Technical Officer, Vienna Unamba, highlighted its versatility in both teaching and research: “Our civil engineering students use the FC80.5 to study sediment transport, wave formation, and flow turbulence. With the dye injector, wave generator, and depth gauges, they can visualise concepts like crests, troughs, and sediment dune formation in real time.” She added, “It's incredibly straightforward to use. With just a short walkthrough and access to the manual, staff and students alike are confident operating it independently.”

The 5 Metre Flow and Sediment Transport Channel (FC80.5) is complemented by a standard 5 metre flume (FC50), which allows students greater flexibility in designing and conducting their own research-led investigations, particularly in final-year project work.

Pipe Friction and Pressure Losses: Applications Across Engineering Disciplines

Understanding fluid behaviour in enclosed systems is a foundational topic for engineers across multiple sectors—from water utilities and building services to automotive and aerospace design. TecQuipment’s Fluid Friction Apparatus (H408) introduces students to the complexities of pressure loss in various pipe configurations, including bends, sudden contractions, and enlargements. This apparatus enables rapid testing of up to 16 different pipework conditions, with pressure tappings positioned before and after each change. By analysing the pressure differential, students learn to quantify frictional losses and relate these to flow characteristics and pipe geometry.

For more focused investigation, the Friction Loss in a Pipe Apparatus (H7) demonstrates the impact of pipe diameter on head loss. A narrower pipe amplifies the frictional effects, allowing students to manually measure flow rate via water collection and weight calculation—linking experimental data back to fluid mechanics theory.

Real-World Understanding of Pipe Flow

Principal Technical Officer, Lewis Batt, talks us through how the Fluid Friction Apparatus (H408) is used to demonstrate flow characteristics within pipes—a crucial topic for any discipline involving fluid transport.

“This kit simulates a variety of pipe environments—from sudden enlargements to sharp bends. Students can quickly measure the effects of each on flow rate and pressure loss. Whether you're designing engines, water distribution systems, or aircraft fuel lines, these lessons are essential.”

Alongside it, the Friction Loss in a Pipe (H7) unit further reinforces these fundamentals. “It’s deliberately designed with a small diameter pipe to magnify friction effects,” Lewis explained. “Students calculate flow rate by collecting and weighing the discharged water—a hands-on task that sharpens both their analytical and practical skills.”

A Testament to Longstanding Support

With years of experience working with TecQuipment, the University of Hertfordshire's technical staff continue to value not only the equipment but the comprehensive support behind it. “I’ve never had anything but fantastic customer service from the sales, technical and installation teams,” Alex concluded. “From setup to student engagement, TecQuipment just makes it work.”

Integrated Engineering Education

Together, these practical experiments form the backbone of a well-rounded engineering education at the University of Hertfordshire. The Spectra building supports students from a wide range of disciplines, reinforcing foundational knowledge through tactile, visual learning experiences.

Whether calculating frictional head loss, measuring sediment transport rates, or evaluating the efficiency of a refrigeration cycle, students are actively applying the theories taught in lectures to hands-on experiments. The result is a learning environment that not only prepares students for academic success, but also for the challenges of engineering in the real world.

Learn More:

Interested in setting up a hydraulics or thermodynamics lab like the University of Hertfordshire? Explore our full product range here.

Learn more about the University of Hertfordshire itself: University of Hertfordshire and its Spectra building: Spectra: Herts’ new flagship building | About us | Uni of Herts