Experiment

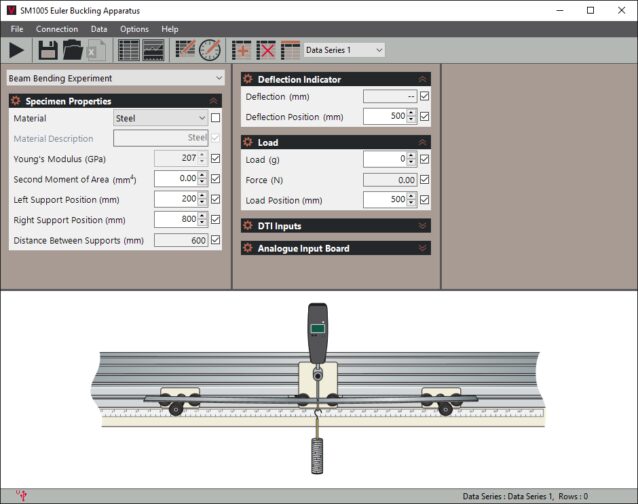

SM1005

EULER BUCKLING APPARATUS

Shows the various modes of buckling (elastic collapse or crippling) of slender compression members.

If you have any questions or you'd like to discuss a product, please call us.

+44 1159 722 611EULER BUCKLING APPARATUS

The SM1005 Euler Buckling Apparatus allows tests on a full range of struts. It shows load and deflection characteristics and buckling loads for various strut lengths, cross-section and end conditions. It also allows studies of the effect of eccentric loading.

An optional set of extra struts (SM1005A) allows extra tests to show students some of the more complicated problems found in strut design.

The main part of the apparatus is a precision-engineered rigid aluminium base, with legs and levelling feet. At one end is a loading device which uses a screw to apply loads to the struts. The screw is in fixing blocks with bearings to give precise and easy load application.

At the opposite end is the load measuring device. This is a precision mechanism that resists the bending moments produced by the struts as they deflect, and transmits the pure axial force to an electronic load cell. This gives an accurate measurement of buckling load. A digital load meter (DL1 – included) shows the load.

Students may move the load-measuring device along the base to work with struts of different lengths and fixing conditions.

A digital dial indicator fixed to a movable slide measures the deflected shapes of the struts. A scale shows the position of the indicator. The digital load meter and the digital dial indicator can connect to TecQuipment’s optional VDAS® (Versatile Data Acquisition System). Holders are at both the loading and load measuring ends. They allow students to create any combination of ‘pinned’ or clamped end conditions for the strut under test. Supplied is a set of special end fittings for tests with various eccentricities to show the effect of eccentric loading. The equipment includes a lateral pull attachment for students to apply light biasing loads, or larger side loads, as needed.

Students can also set up the apparatus to examine flexural rigidity and general beam deflection theory.

The standard set of ten struts (supplied) covers the primary variables of length, cross-section and end conditions. The optional set of additional struts (SM1005A) includes struts of different materials, typical engineering sections, and two special struts.

The two special struts show how buckling loads may be lower than the ideal values, because of two reasons:

- Flexure of the end fixings

- Imperfect shearing connections between the parts of a compound strut

For quick and reliable tests, TecQuipment can supply the optional VDAS® (Versatile Data Acquisition System). VDAS® gives accurate real-time data capture, monitoring and display, calculation and charting of all important readings on a computer.

Learning outcomes

With the standard set of ten struts:

- Demonstration of buckled (crippled) shape of struts with different end conditions.

- Determination of load/deflection curves and buckling loads for struts of different lengths and cross-sections, with any combination of ‘pinned’ or clamped end fixings.

- Comparing experiment results with those using Euler’s buckling theory

- Investigation of the effects of side load and eccentric loading on strut buckling characteristics.

- Flexural rigidity and buckling loads for struts of different materials.

- The use of Southwell’s method to estimate buckling loads and strut eccentricities from experimental results.

- Determination of flexural rigidity and comparison with calculated values.

- Deflections of a simply supported beam with a point load including the verification of general deflection formulae, and the deflected shape.

With the SM1005A optional set of additional struts:

- Flexural rigidity and buckling loads for struts of a further range of different materials.

- Tests on typical engineering sections (circular, angle, channel and irregular section specimens)

- the significance of the neutral axes

- combined bending and twisting due to eccentric loading.

- The effect of flexibility in end fixings.

- Tests on a compound strut with imperfect shearing connections between the two components.